Ritetack Instant Grab Construction Adhesive

$18.31 – $34.81 Excludes GST

SKU: ET6-5000, ET6-5000B, ET6-5000G, ET6-5001

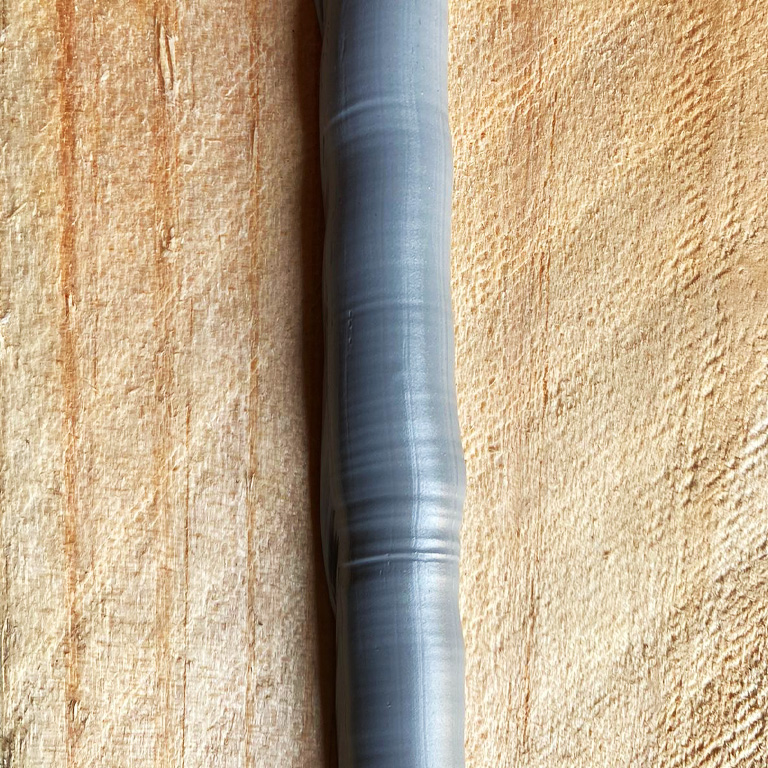

Available in White, Black, and Grey (290ml and 600ml)

- Eliminates the need for unsightly fixings or tiresome clamping & propping

- Superior initial grab, up to 1000KGS per SQM horizontally

- Suits most materials including timber, metal, glass, mirror, plaster, stone, ceramic, concrete, PS, PU, PVC & polystyrene.

- No solvents & no isocyanate, user-friendly!

- Proven worldwide

- Paintable & retains elasticity

The best construction adhesive in the market!

Ritetack is an odorless and silicone, solvent, phthalate, PVC, and isocyanides-free, high-quality instant grip polymer adhesive designed for the building and construction industry, which performs. There is no need to wait while it cures since you only need to apply Ritetack, position it, and that’s it, no need for any type of braces.

Ritetack is DIY and home improvement’s go-to glue. This instant grab adhesive works with most materials from stone and timber to steel and plasterboard, and more, it’s so easy to apply. Use it in with your caulking gun, like the Ritepro, on any job.

If you want a glass adhesive, it is your answer. Less hassle, less labor, and fewer fixings. Used for mirror installation by the glass industry.

Construction Adhesive Ritetack is available to buy 24/7 online, so whether you are in Perth or Sydney, or anywhere in between, we can deliver Ritetack Adhesive to your door. When you want one adhesive that you can rely on, you don’t have to go far, because Ritetack is proven worldwide, and its success is based on it delivering what it says it can do – instantly!

Its coloured, elastic composition is a combination of cutting-edge adhesive technology and our market-leading easy-to-use design.

When you want to know that you have proven adhesive which you can rely on, Ritetack will be your answer.

Alternative to Liquid Nails and T-Rex Adhesive.

What is your trade? It’s covered! Used by DIY, home improvement, architectural, shopfitting, signage and display installers, steel industry, marine, mining, plumbing, general industry, transport…you name it, you will use it!

Ritetack is available to buy online or walk into your local hardware to purchase.

Ritetack is the leading product in the Rite Adhesives range, which reduces build time.

To keep up to date with our promotions, rebates, and news, don’t forget to follow us on LinkedIn.

Specifications

Download TDS Download SDS Download Application GuidePhysical properties

- Colour: White, Black and Grey

Performance properties

- Tensile strength: 2.2N/mm2

- 100% Modulus: 1.4N/mm2

- Elongation at break: 335%

- Application temperature: 5°C to 40°C

- Temperature resistance after curing: -40°C to 100°C

- Density: 1.57g/ml

- Skin over time: 10-15 minutes after application

- Curing after 24 hours: 3mm

- Shore A hardness: 55

- UV, weather, and water-resistant: Yes

Available sizes

- Tube: 290ml

- Sausage: 600ml

- 1 box equals 12 tubes

Application

It is advised that Ritetack is applied with a heavy-duty applicator, like the Ritepro. Ritetack has to be applied in volumes relating to the material surface and weight of the object. Ritetack has to be applied through large nozzles. Normally it is applied in strips approx. 20mm apart then the 2 materials are pressed together firmly so that the thickness is no thinner than 3mm. Ritetack should not be applied in dots. If applied correctly no support is required during curing.

Storage and Shelf Life

18 months if kept in a cool, dry place and stored in temperatures between +5C to +25C.

Videos

Delivery

No delivery surcharge on orders over $98. If the amount is not reached, a single $18 fee will be applied to your total.

For more information please access our Shipping and Returns T&C page.