News

The Differences Between Bond Failures

MS polymers, also known as “Modified Silicone”, take a different approach compared to traditional options like silicone or polyurethane. They’re formulated with a modified silane polymer base, which gives them a unique blend of benefits.

MS polymers exhibit exceptional flexibility, allowing them to accommodate variations in temperature and humidity, absorb vibrations caused by structural movement, impacts, and sound. Coupled with their UV stability and abrasion resistance akin to polyurethanes, MS polymers provide excellent durability and weather resistance.

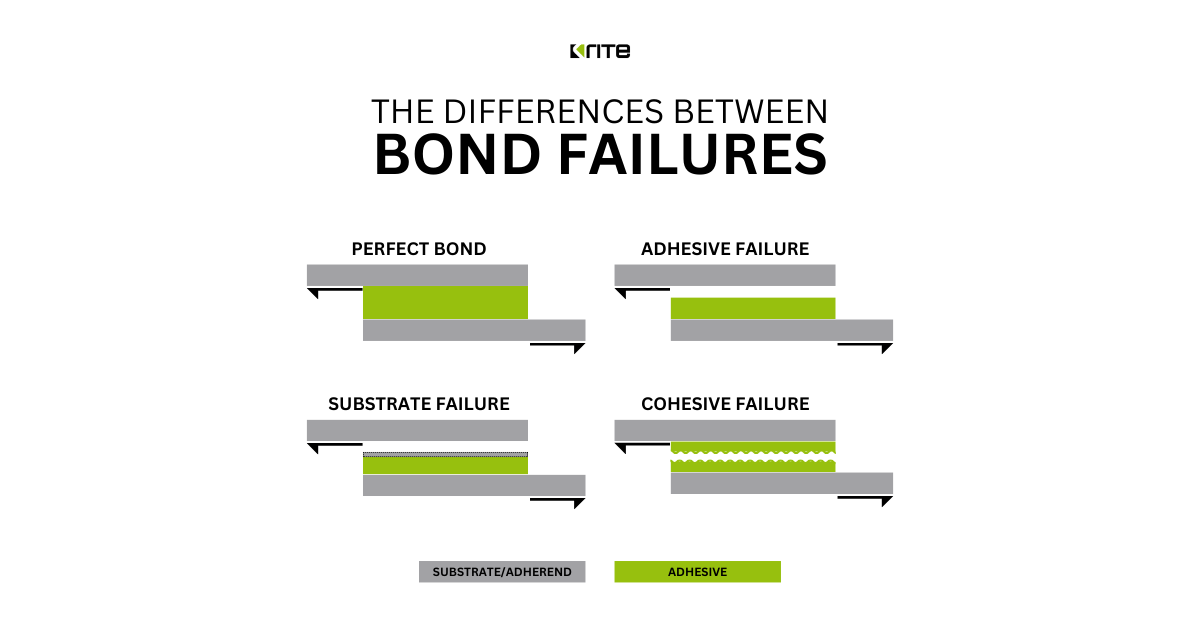

When it comes to bond failures, there are three main types to consider;

- Adhesive Failure – The bond failure occurs at the interface where the adhesive meets the substrate (adherend), typically marked by a clean separation between the adhesive and the substrate. Example: Ritetack being used with Concrete (compatible) and PET (not compatible).

- Cohesive Failure – The bond fails within the adhesive itself, characterized by a separation that occurs within the adhesive material.

- Substrate/Adherend Failure – The bond failure arises from the substrate’s failure while the adhesive remains intact. Following separation, the adherend remains attached to the adhesive. Example: Ritetack being used to stick an ACM sheet to an unprepared rendered wall, the ACM panel comes off, with all the sand, etc stuck to the adhesive.

Each of these failure modes presents its own set of challenges and requires specific attention to address effectively.